Need more infomation? Connect with us now.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Proin lorem elementum iaculis quam justo dictumst nostra

Proin lorem elementum iaculis quam justo dictumst nostra

Proin lorem elementum iaculis quam justo dictumst nostra

Proin lorem elementum iaculis quam justo dictumst nostra

High Pressure Die Casting (HPDC) is a manufacturing process designed for large-scale or mass production, typically using casting alloys with low melting points.

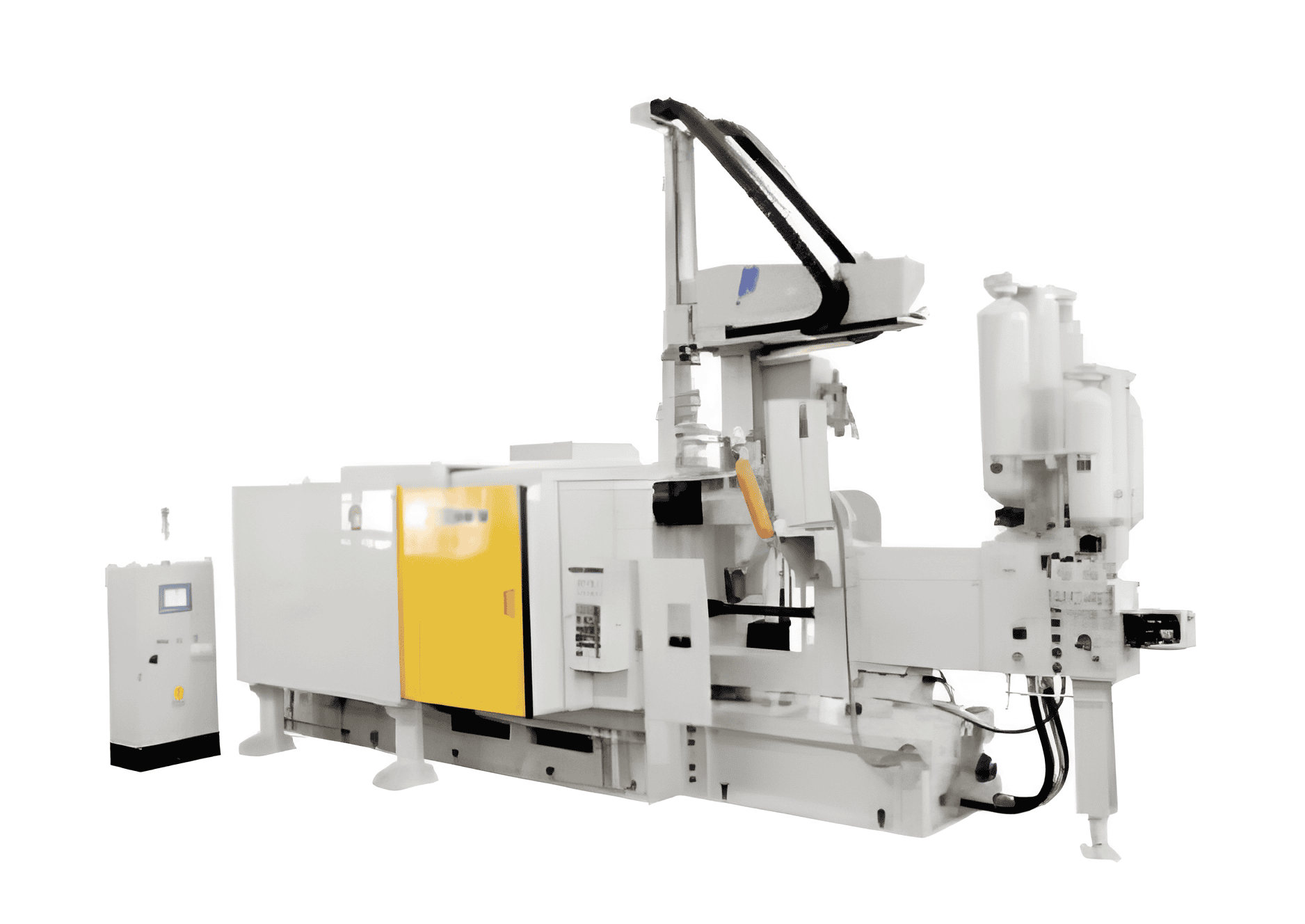

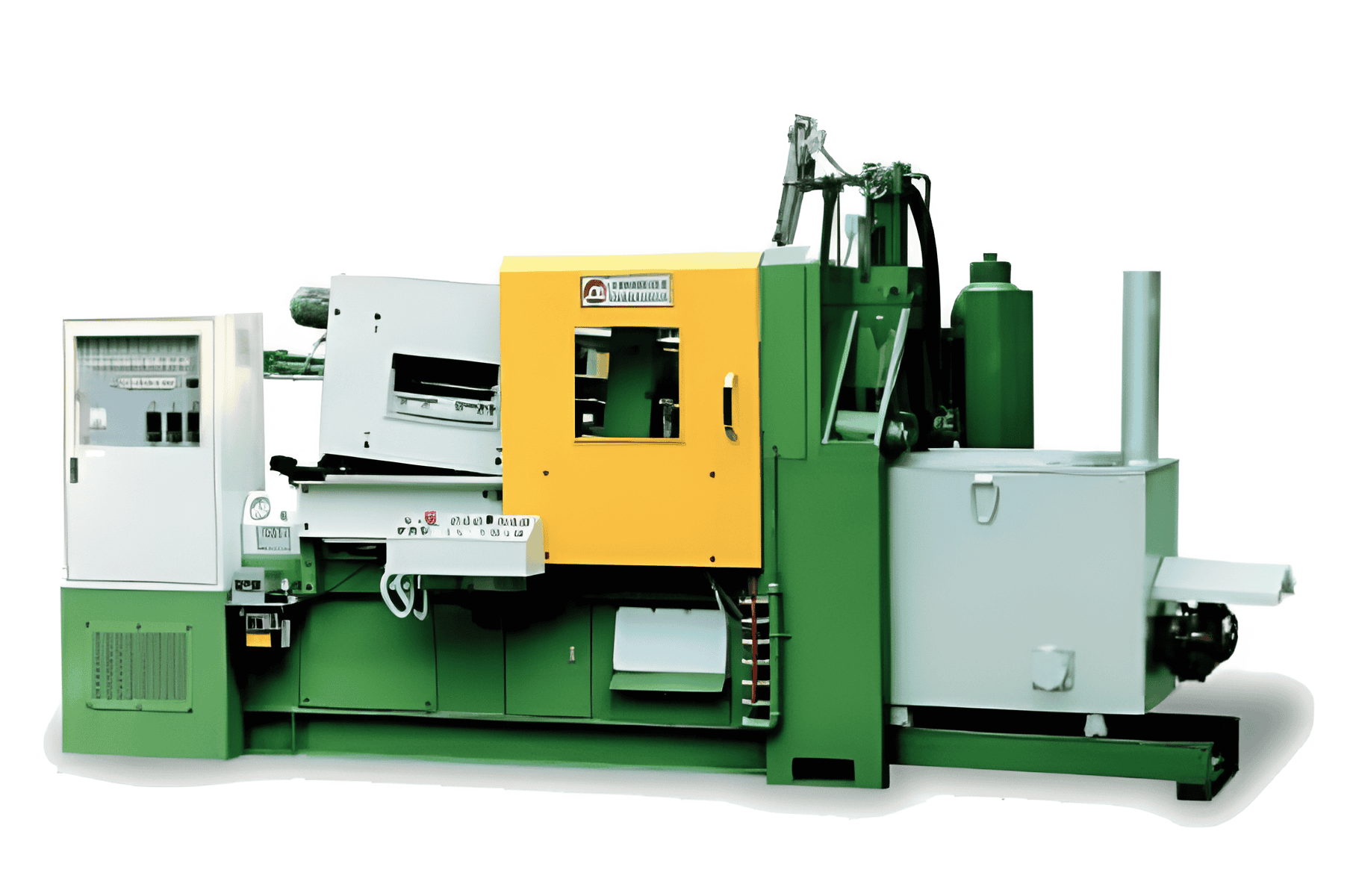

In this method, molten metal is injected into a casting mold under high pressure, ranging from approximately 10 to 200 MPa, and at a rapid filling speed of up to 12 m/s, where it solidifies. A distinctive feature of die casting is that it employs a permanent mold, meaning no model is needed. Consequently, the mold is created just once for a series of identical components, resulting in higher initial production costs but significantly increased output. This is particularly true for hot-chamber die casting machines, where the casting chamber and plunger remain immersed in molten metal. For alloys with higher melting points, the cold-chamber die casting process is used, where the casting equipment operates outside of the molten metal.

Cold chamber die casting is a manufacturing process used to create metal parts with high precision and excellent surface finishes. It involves manually pouring molten metal into a cold chamber, where a piston injects it into a die at high pressure. The metal then cools and solidifies in the die before being ejected. Overall, cold chamber die casting is effective for producing high-quality metal components.

Hot chamber die casting is a manufacturing process used to produce metal parts, particularly those made from low-melting-point metals like zinc and lead. Molten metal is maintained in a chamber that is heated, allowing for continuous feeding into the die. A plunger injects the molten metal directly into the die under high pressure, minimizing the risk of oxidation and improving cycle efficiency.

Overall, hot chamber die casting is an efficient method for producing precise metal parts, especially for specific alloys.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Nullam semper vitae enim orci porttitor senectus pede bibendum pharetra ullamcorper aliquam quis letius nunc nam cursus ultrices

Nullam semper vitae enim orci porttitor senectus pede bibendum pharetra ullamcorper aliquam quis letius nunc nam cursus ultrices

Nullam semper vitae enim orci porttitor senectus pede bibendum pharetra ullamcorper aliquam quis letius nunc nam cursus ultrices

Nullam semper vitae enim orci porttitor senectus pede bibendum pharetra ullamcorper aliquam quis letius nunc nam cursus ultrices

Shanghai Gongfu Industries Co.,Ltd

5B, Jalan Cipta Serenia 3C, Pusat Perindustrian Cipta Serenia,

43900 Sepang, Selangor, Malaysia.

Tel: +86 (0)21-57291664

Fax: +86(0)21-57292121

Email: xh.l@www.gfi-auto.com

Shanghai Gongfu Industries Co.,Ltd

5B, Jalan Cipta Serenia 3C, Pusat Perindustrian Cipta Serenia,

43900 Sepang, Selangor, Malaysia.

+6221.2002.2012 +6221.2002.2013

support@yourdomain.tld hello@yourdomain.tld

Jalan Cempaka Wangi No 22

Jakarta - Indonesia

Sign up our newsletter to get update information, news and free insight.